AN INTERVIEW WITH DR. OLGA KOPER,

Business Development/Sales Leader Energy, Battelle

BREAKTHROUGH GREEN CHEMISTRY SOYBEAN-BASED SURFACTANT UNDER DEVELOPMENT AT BATTELLE

Dr. Koper has a Master of Sciences in General Chemistry from Silesian University, Poland and a Doctor of Philosophy in Inorganic Chemistry from Kansas State University. In 2013, she was awarded The White House Champions of Change Award for Immigrant Innovators and was chosen by Entrepreneur Magazine as one of seven selections for 2013's Entrepreneurial Women to Watch. She is proposal reviewer for the Department of Defense, National Cancer Institute, and European Commission.

Dr. Olga Koper is responsible for the development and implementation of Battelle’s technologies related to advanced materials and technologies for the oil and gas exploration and production industry. She has designed nanomaterials for sweetening of natural gas, water and air filtration, biomass conversion, decontamination of toxic chemicals and biological species, as well as cancer detection and treatment. These activities resulted in over 30 issued U.S. and international patents and 34 peer-reviewed publications.

Some examples of Dr. Koper’s research activities include development of self-healing cement for enhancing wellbore integrity, development of a platform membrane technology for water treatment applications (forward osmosis, reverse osmosis and nanofiltration) for treatment of flowback and produced water from the shale gas industry, utilization of nanoscale metal oxides and carbon nanotubes for supercapacitor electrodes, development of reactive nanoparticles as destructive adsorbents for biological and chemical decontamination. This work resulted in commercialization of a hazard mitigation product (FAST-ACT) as well as several patent and peer-reviewed publications. Development of catalytic topical skin cream protectants based on nanoparticles, as well as nanoparticles and polyoxometalate combinations: This work was carried out in collaboration with Emory University, leading to two patents jointly owned with the Department of Defense.

Her research has been done in several diverse fields of application. She has designed nanomaterials that can be incorporated into fabric, such as for soldier uniforms, to protect and decontaminate toxic materials. She has worked on nanomaterials for batteries, supercapacitors, air filtration applications, chemical and biological decontamination, natural gas and oil recovery, water purification, and catalysis. Further, Koper has applied nanomaterials to cancer diagnosis and treatment, using functionalized core/shell magnetic nanomaterials to detect over-expressed proteases. The resulting product is injectable, and during surgery can be used to fluoresce and define malignant cells, thus allowing surgeons to fully clear the margins of a cancerous mass.

BATTELLE MEMORIAL INSTITUTE

As the world’s largest, independent research and development organization, Battelle provides innovative solutions to the world’s most pressing needs through its four global businesses: Laboratory Management; National Security; Health and Life Sciences; and Energy, Environment and Material Sciences. It advances scientific discovery and application by conducting $6.5 billion in global RnD annually through contract research, laboratory management and technology commercialization. Headquartered in Columbus, Ohio, Battelle oversees 22,000 employees in more than 130 locations worldwide, including seven national laboratories which Battelle manages or co-manages for the U.S. Department of Energy and the U.S. Department of Homeland Security and a nuclear energy lab in the United Kingdom.

Battelle also is one of the nation’s leading charitable trusts focusing on societal and economic impact and actively supporting and promoting science, technology, engineering and mathematics (STEM) education.

Every day, the people of Battelle apply science and technology to solving what matters most.At major technology centers and national laboratories around the world, Battelle conducts research and development, designs and manufactures products, and delivers critical services for government and commercial customers. Headquartered in Columbus, Ohio since its founding in 1929, Battelle serves the national security, health and life sciences, and energy and environmental industries. For more information, visit www.battelle.org

Can you elaborate on the soy based surfactant that is looking very promising for a new green chemistry method?

Battelle is working on developing sustainable oilfield chemicals to reduce production costs as well as environmental impact while improving chemical performance. One such product is a cationic surfactant from soybean oil. The material has been formulated and it being tested for multiple oilfield applications.

How is this new surfactant developed?

Soybean oil, which is used as feedstock, is processed to yield a cationic surfactant. This surfactant is then blended with a co-solvent to optimize its solubility in water as most hydraulic fracturing fluids are water-based.

What are the initial results and how is this a better or "greener" method?

The surfactant is designed based on the principles of green chemistry. Our initial test results suggest the soy-based cationic surfactant shows no signs of estrogenic or anti-estrogenic activity based on BG1 Luc estrogen receptor transactivation test. Hence, our product is showing signs of promise of a greener technology as opposed to conventional cationic products.

Which companies are working on this project and how soon might it be used commercially? What benefits will it have over the current products being used

Currently, Battelle is in talks with a variety of oilfield chemical companies and operators to further develop and optimize this technology. The technology is still in early stages of development. Time to market will depend on a host of factors, such as the technical progress during the next stage of development, commitment of the commercial client and the specific application of the product, i.e., enhanced oil recovery. The benefits of using this product include

• Lower production costs

• Reduced environmental impact

• Multiple wellbore applications

• Flexibility in surfactant design

What new technologies is Battelle working on related to nanotechnology? Not just in oil and gas but in other areas as well.

Nanotechnology is part of many applications, from design of catalysts to new sensors. One specific example is anti-icing and deicing technology for in-flight aircrafts based on a resistive heating using carbon nanotubes. This innovative coating solution is small in size, weight and power envelope and has unmatched performance in the industry. This coating can be used on drones when the weight constrains are of paramount importance.

And what do you see as the emerging trends in nanoscience that will revolutionize the world of engineering and have a big impact on society?

The largest impact is related to medicine, and particularly to drug delivery and early detection, particularly non-invasive using biomarkers. For example, designer nanoparticles can target specific cancer cells increasing treatment effectiveness and decreasing the side effects. Other areas are energy related, such as in energy storage (battery interfaces in Li-ion batteries) and harvesting (solar cells).

What are nanofluids and how are they used to enhance oil recovery? Why are they called smart fluids?

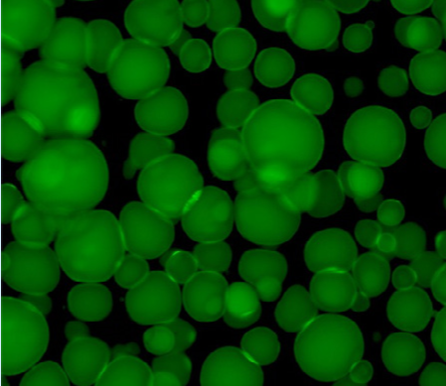

Nanofluids are solutions of nanoparticles (1-100 nm in dimension) and can be used in a variety of oilfield applications such as drilling, stimulation and improving oil recovery. Silica nanoparticles can alter the rock wettability of oil-wet reservoir rocks to water-wet thereby reducing the tendency of the rock to stay in contact with oil. This will eventually lead to higher oil recovery. Nanofluids also help control the mobility of injection fluids which in turn improves the sweep efficiency of injectates and therefore the resulting oil/gas recovery. However, a definition of smart fluids can be much broader and include materials that upon a stimuli will perform specific actions. This could include a controlled release from nano or micro capsules upon exposure to specific temperature, pressure, presence of ions, or other chemicals.

Pictured: Smart nanobeads

Why does the size of the nanoparticles matter, and how is it measured? Do you use atomic force microscope?

For specific applications the size of the particles is crucial. For example, with carbon nanotubes in the deicing coating, the small size will provide lower weight of the coating, which is particularly important for drone applications, to extend the battery life during flights. In drug delivery applications not only size, but also shape and surface chemistry have a large impact on cellular uptake and overall treatment efficiency. Such correlations are studies using many methodologies including AFM.

How does the oil and gas industry use controlled release methods or encapsulation for oil production and why? Can you give examples?

An example of a controlled release can be delivery of the anti-scaling agents at the desired place and time. The controlled release can use different trigger mechanisms including temperature, pressure, presence of specific ions, etc. The type of the trigger is usually chosen based on the desired parameters, i.e., if you want the active ingredient to be released uniformly over a two-year period of time, or if you want to release it abruptly when the material reaches downhole conditions (specific temperature and pressure). The encapsulation approach eliminates using excess quantities of materials (cost savings and environmental benefits) as well as decreases labor associated with reapplication.

Photo Caption: Pictured above left to right, Ram Lalgudi and Manoj Valluri from Battelle contributed to this article.