Park NX-3DM Specifications

System

Specification

Motorized XY stage

200 mm: travels up to 275 mm × 200 mm,

0.5 μm resolution

300 mm:travels up to 400 mm × 300 mm,

0.5 μm resolution, < 1 μm repeatability

Motorized Focus Stage

9 mm Z travel distance for on-axis optics

Motorized Angle Range

-19 degrees and +19 degrees

-38 degrees and +38 degrees

< 0.5 degree angle repeatability

Motorized Z Stage

27 mm Z travel distance

0.08 μm resolution

< 1 μm repeatability

Z Scanner

Z Scanner Range: 15 μm (large mode)

2 μm (small mode)

Z Scanner Resolution: 0.016 nm (large mode)

0.002 nm (small mode)

Z Scanner Noise Floor: < 0.05 nm

Z Scanner Detector Noise: 0.03 nm, rms (typical)

COGNEX Pattern Recognition

pattern align resolution of 1/4 pixel

Scanner Performances

XY Scanner

Single-module flexure XY scanner with closed-loop control

100 µm × 100 µm (Large mode)

50 µm × 50 µm (Medium mode)

10 µm × 10 µm (Small mode)

XY Scanner Resolution

0.28 nm (Large mode)

0.03 nm (Small mode)

Facility Requirements

Room Temperature (Stand By)

10 °C ~ 40 °C

Room Temperature (Operating)

18 °C ~ 24 °C

Humidity

30% to 60% (not condensing)

Floor Vibration Level

VC-D (6µm/sec)

Acoustic Noise

Below 65 dB

Pneumatics

Vacuum : -80 kPa

CDA (or N2): 0.7 MPa

Power Supply Rating

208V - 240 V, single phase, 15 A (max)

Total Power Consumption

2 KW (typical)

Ground Resistance

Below 100 ohms

Options

Automatic Tip Exchange (ATX)

Automatic Tip Exchange performs fully automated tip exchanges in order to seamlessly continue automated measurement routines. It automatically calibrates cantilever location and optimizes measurement settings based on measurements of a reference pattern. Our novel magnetic approach to the tip exchange yields a 99% success rate, higher than the traditional vacuum techniques.

Automatic Wafer Handler (EFEM or FOUP)

The XE-3DM can be further customized by adding an automatic wafer handler (EFEM or FOUP or other). The high-precision, nondestructive wafer handler robot arm fully ensures XE-3DM users to receive fast and reliable wafer measurement automation.

Ionization System

Ionization system effectively removes electrostatic charges. It ionizes the charged objects and is very reliable since the system always generates and maintains an ideal balance of positive and negative ions without causing any contamination to the surrounding area. It also reduces the accidental electrostatic built-in charge that may occur during sample handling.

Dimensions & Weight

200 mm System

1500 mm(w) × 980 mm(d) x 2050 mm(h)

w/o EFEM, 1020 kg approx. (incl. Control Cabinet)

2465 mm(w) × 1000 mm(d) x 2050 mm(h)

w/ EFEM, 1230 kg approx. (incl. Control Cabinet)

Ceiling Height

2500 mm or more

Operator Working Space

3300 mm (w) x 2300 mm (d), Minimum

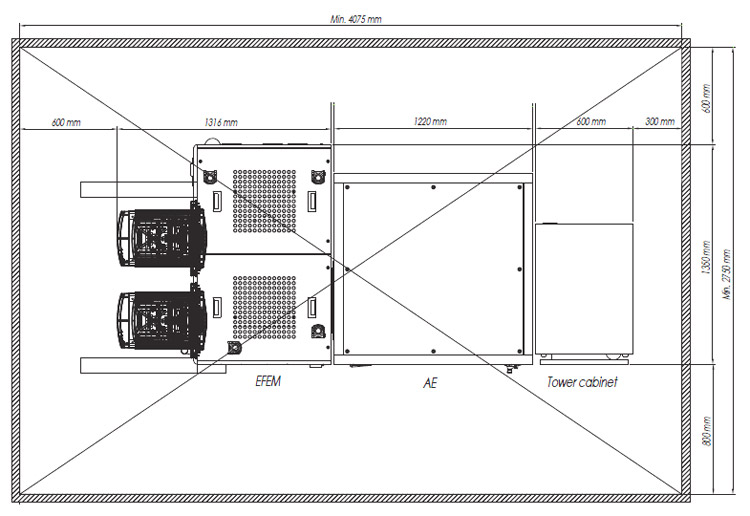

300 mm System

1840 mm(w) × 1170 mm(d) x 2050 mm(h)

w/o EFEM, 1320 kg approx. (incl. Control Cabinet)

3260 mm(w) × 1350 mm(d) x 2050 mm(h)

w/ EFEM, 2120 kg approx. (incl. Control Cabinet)

Ceiling Height

2500 mm or more

Operator Working Space

4540 mm (w) x 2850 mm (d), Minimum

[ Park NX-3DM 300mm installation layout ]

[ Park NX-3DM 300mm installation layout ]