The fully Automated Tip Scanning Head for OLED, LCD, and 2D encoder sample

Developed specifically for manufacturers setting up fabs to produce next-generation flat panel displays

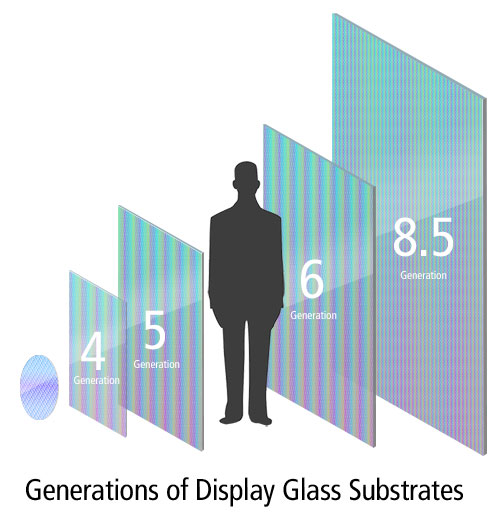

Park Systems has scaled up their AFM tools for Gen8+ and all large flat panel displays using Park NX-TSH (Tip Scanning Head) system, and is the fully automated Tip Scan Head for large sample analysis. It was developed specifically for manufacturers setting up fabs to produce next-generation flat panel displays with the objective to overcome the 300mm size threshold limit.

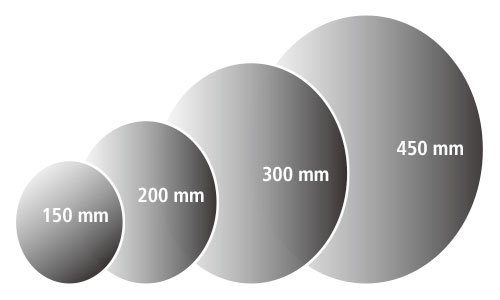

Changes in the silicon wafer diameter

Using conductive AFM, Park NX-TSH can measure the sample surface with optional probe stations that contact the sample surface and provide current into small devices or chips of wafer level. Park NX-TSH is for a 2D encoder sample with conductive AFM for electric defect analysis by integrating micro probe stations.

Park NX-TSH features

Overcomes the limitations of sample size and weight

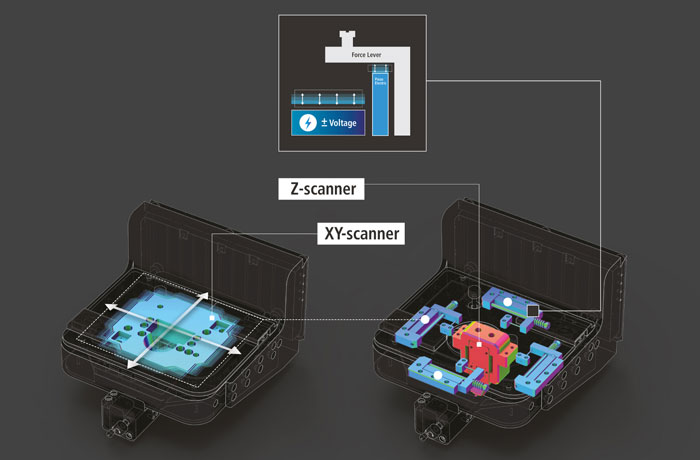

The newly developed Tip Scanning Head by Park Systems combines X, Y and Z scanners, moving directly to the desired point. Park NX-TSH can scan tip itself in X, Y and Z directions, up to 100 µm x 100 μm (x-y direction) and 15 μm Z-direction, and has flexible chuck to accommodate large and heavy samples over 300mm developed for OLED, LCD for large sample analysis. The sample is fixed on a sample chuck and the tip scanning head attached to the gantry moves to measurement positions on the surface sample. The Park NX-TSH tip scanning head system therefore overcomes the limitations of sample size and weight since the sample is fixed on the sample chuck.

100 µm x 100 µm Flexure-Guided XY Scanner with Closed-loop Control

The XY scanner consists of symmetrical 2-dimensional flexure and high-force piezoelectric stacks that provide highly orthogonal movement with minimal out-of-plane motion, as well as the high responsiveness essential for precise sample scanning at the nanometer scale.

15 µm High Speed Z Scanner with Low Noise Position Sensor

The NX-TSH provides you with unprecedented accuracy in topography height measurement by utilizing its ultra-low noise Z detector instead of the commonly used Z voltage signal that is non-linear in nature. This industry leading low noise Z detector replaces the applied Z voltage as the topography signal.

Long Range Air-bearing XY stage for AFM analysis of industrial samples larger than 300 mm.

Park NX-TSH overcomes nano metrology challenges of large and heavy sample with Tip Scanning Head and a gantry style air-bearing stage and produces high resolution images. The air bearing stage technology provides faster access and a fully automated system, improving productivity.

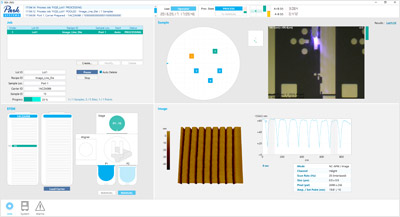

Automatic Measurement Control so you can get accurate scans with less work

The NX-TSH is equipped with automated software that makes operation nearly effortless. Just select the desired measurement program to get precise multi-site analysis with optimized settings for cantilever tuning, scan rate, gain, and set point parameters.

The NX-TSH is equipped with automated software that makes operation nearly effortless. Just select the desired measurement program to get precise multi-site analysis with optimized settings for cantilever tuning, scan rate, gain, and set point parameters.

Park's user-friendly software interface gives you the flexibility to create customized operation routines so you can access the full power of the NX-TSH and get the measurements you need.

Creating new routines is easy. It takes about 10 minutes to make one from scratch, or less than 5 minutes to modify an existing one.

Park NX-TSH’s automated system features:

• Auto, semi-auto, and manual mode so you have complete control

• Editable measurement method for each automated routine

• Live monitoring of the measurement process

• Automatic analysis of acquired measurement data